Production Knife Design

Skills Involved

Project Management

Maintain relationships with manufacturers overseas, market my designs to manufacturers, negotiate contracts

Mechanical Design

DFM, design of locking and deployment mechanisms, CAD modeling, implement design feedback from manufacturers

Creative Design

Understanding aesthetics and product design, sketching, 2D CAD, rapid prototyping of designs

What do you mean you design Knives?

The Pocket Knife Industry

Globally the pocket knife industry has a $600 million USD value. The USA accounts for almost 25% of that market and a majority of the sale of my designs.

My Role

As a knife designer I must understand what makes a good pocket knife, and try to translate that into a new design. Using sketches and CAD, I take my ideas and create drawings to present to pocket knife companies. Currently, four companies licence my designs, then manufacture and sell the final product. In a new design I am looking for functionality, ergonomics, overall design weight and importantly knife aesthetics.

From Idea to Market

Why design pocket knives?

Pocket knives are like watches. If you just need to tell the time you can use your phone. If you like a watch you can get quality one for $50. If you want to impress people you can get a Rolex. All tell the time, some are more function-focused while other options are more for show or user experience. Pocket knives are the same. A butter knife or exacto knife will do the job. Maybe you want something simple like a Swiss Army Knife or one of my designs. Or maybe you want to spend a lot of money for a blade with gold inlays and gemstones…

Designing pocket knives allows me to combine mechanical design work with aesthetics and creativity. Knives are a true combination of form and function. When I started designing knives I had access to a workshop and loved being able to take my designs and combine woodwork, metalwork and material science (heat treating) to bring them to life as a work of functional art. During Covid, I lost access to a workshop, leading me to pivot to designing folding knives and eventually I started submitting my designs to companies.

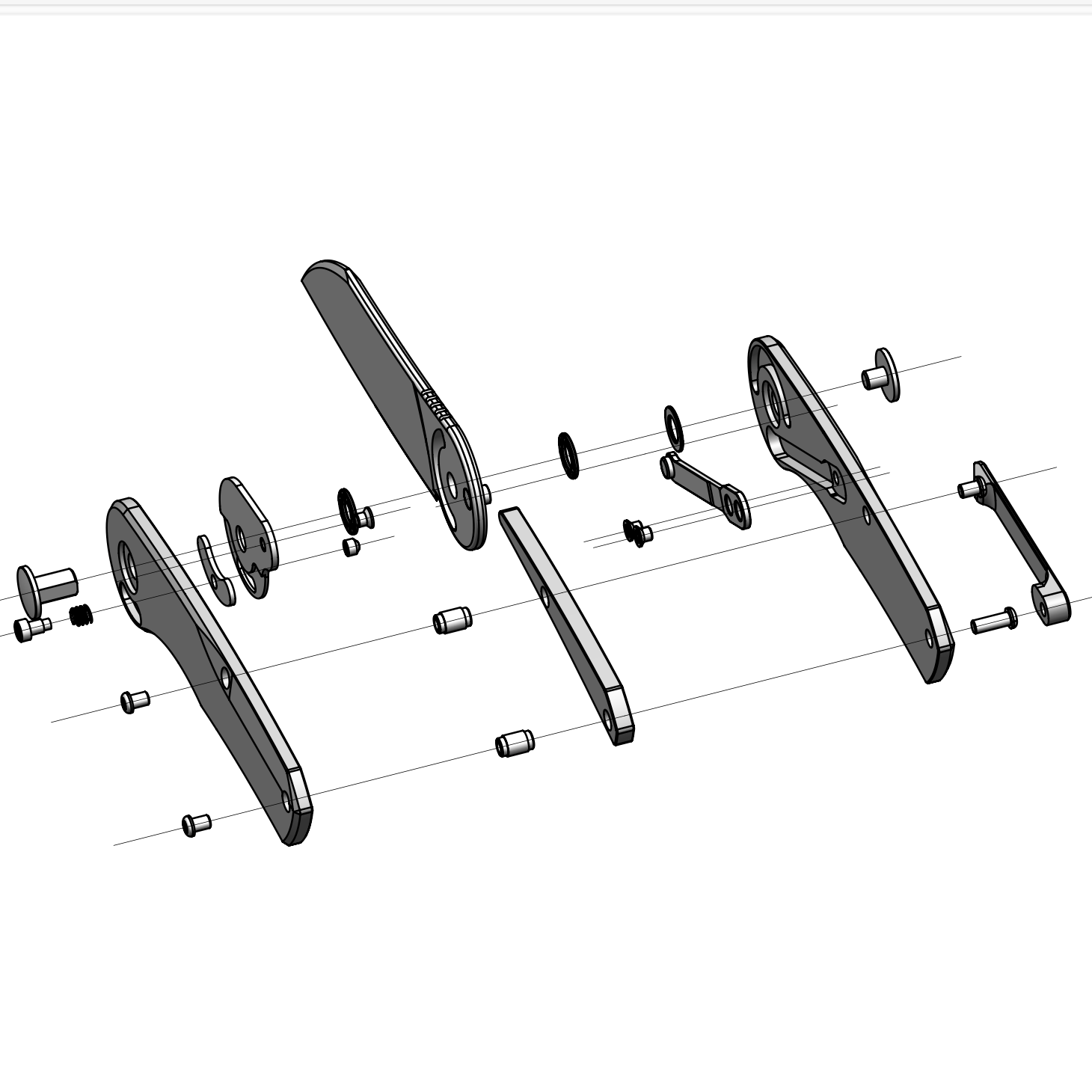

Designing a pocket knife

Most of my designs start as a doodle or a sketch in a notebook and from these sketches I identify curves and formes that stand out. When I find a profile or feature I want to explore more I bring it into CAD and work out the details of the design. I make sure the blade length meets my target use. I make sure the handle is ergonomic. I check the locking mechanism are functional and manufacturable. All while keeping the aesthetics of the original idea.

Submitting design for consideration

Having completed a promising design, I create renders and a list of specifications I can use to present to my contacts in the industry. Different companies have different styles they prefer and I tailor my submission to match. Once a design is submitted to one of my industry contacts, they present it to their team and let me know if they are interested in taking it on as a project.

Licensing Designs

If a company is interested in one of my designs a contract will be made up specifying the licencing terms. Typically designs are licenced in exchange for some percentage of sales of the final product.

Working with manufacturers

After a contract is signed, I share all my designs files with the company’s R&D team. Their team then creates manufacturing drawings based on their manufacturing capabilities, standard components and industry knowledge. These drawings then go back and forth between myself and the R&D team to ensure the design meets the companies requirements and fits my design vision. Prototypes are made and tested before a production run is scheduled.

Currently, I have eight more designs in various stages of prototyping across four companies.

Market launch!

When the design is launched, companies promote, market the knife and distribute knives to retailers around the globe. Samples of the production knives are sent to me and some are sent to knife reviewers to help raise awareness for the new design.

Market reception

Currently my best selling design is the Kizer Dogfish. As of year end 2024, over a thousand units have been sold. Following the release the “Dogfish” the design received very positive reviews from the knife world and knife reviewers alike.